Acrylic plastic parts have a wide range of uses across various industries and applications. Some common uses of acrylic plastic parts include:

- Signage and Displays: Acrylic is a popular material for creating signs, display cases, point-of-purchase displays, and exhibition stands. Its transparency, durability, and ability to be easily molded make it ideal for showcasing products or conveying information.

- Lighting Fixtures: Acrylic is often used as a replacement for glass in lighting fixtures. It is lightweight, shatter-resistant, and can be shaped into different forms, allowing for the creation of attractive and functional lighting solutions.

- Automotive Applications: Acrylic is used in various automotive components such as headlight lenses, taillight covers, and interior trim. Its high optical clarity and resistance to UV radiation make it suitable for these applications.

- Medical Equipment and Devices: Acrylic is used in the medical field for manufacturing components like clear protective barriers, test tubes, laboratory equipment, and prosthetic devices. Its biocompatibility, ease of sterilization, and transparency are advantageous in medical applications.

- Furniture and Home Decor: Acrylic is commonly used in furniture and home decor items such as chairs, tables, shelves, and decorative accents. Its modern and sleek appearance adds an aesthetic appeal to interiors, and its lightweight nature makes it easy to handle and move.

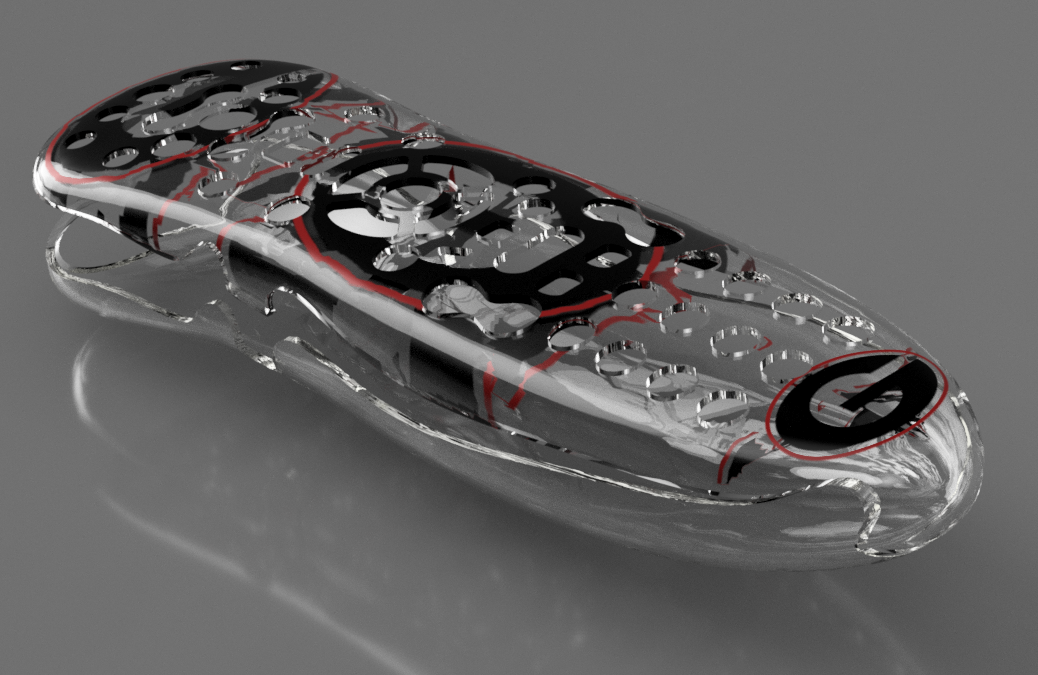

- Protective Guards and Covers: Acrylic is often utilized to create protective covers, shields, and guards for machinery, electronics, and other equipment. Its impact resistance and clarity allow for visibility while protecting sensitive components.

- Aquariums and Aquatic Environments: Acrylic is a popular material for manufacturing aquariums due to its optical clarity and ability to withstand water pressure. It offers a clear view of aquatic life and is lighter and less prone to breakage compared to glass.

- Consumer Goods: Acrylic is used in the production of a wide range of consumer goods such as cosmetic organizers, phone cases, picture frames, and household items. Its versatility allows for the creation of various functional and aesthetically pleasing products.

These are just a few examples of the many applications of acrylic plastic parts. The material's properties, including transparency, durability, versatility, and ease of fabrication, make it a preferred choice in industries requiring visually appealing, lightweight, and impact-resistant components.