A PCB (Printed Circuit Board) enclosure is useful, several reasons why:

-

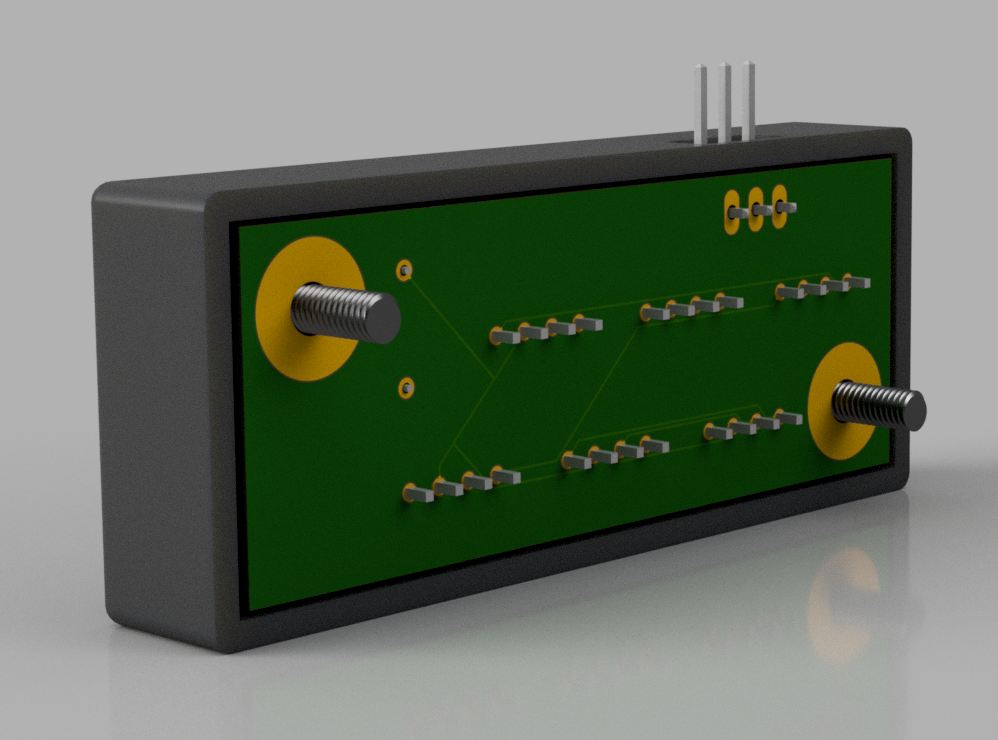

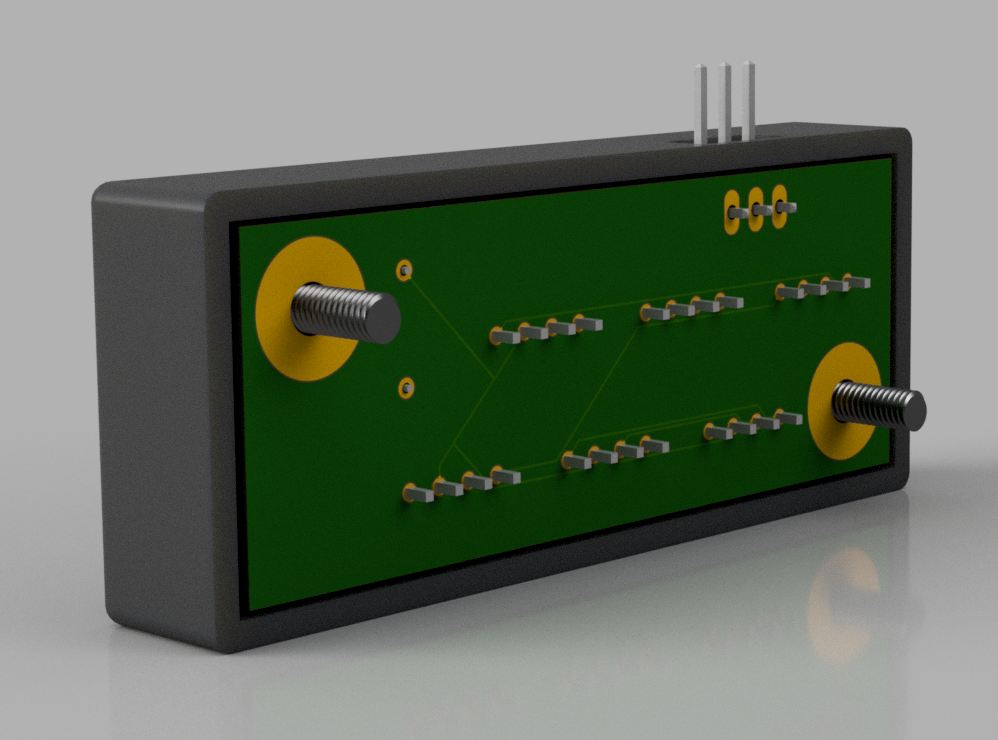

Protection: The enclosure provides physical protection for the PCB and its components. It helps safeguard the board from dust, moisture, mechanical shocks, and other potential hazards. This protection is crucial, especially in industrial or outdoor environments where the PCB may be exposed to harsh conditions.

-

Electrical Safety: The enclosure can offer electrical insulation, preventing accidental contact with live components or exposed circuitry. It helps prevent short circuits, electric shocks, or damage to the PCB due to environmental factors.

-

EMI Shielding: Some PCB enclosures are designed with EMI (Electromagnetic Interference) shielding materials. These materials block or absorb electromagnetic radiation emitted by the PCB and prevent interference with other nearby electronic devices. EMI shielding is particularly important in sensitive applications such as medical devices or communication systems.

-

Compliance with Standards: Enclosures help PCBs meet specific compliance and regulatory standards. Depending on the application, certain certifications or regulations may require PCBs to be enclosed for safety, electromagnetic compatibility, or environmental protection reasons.

-

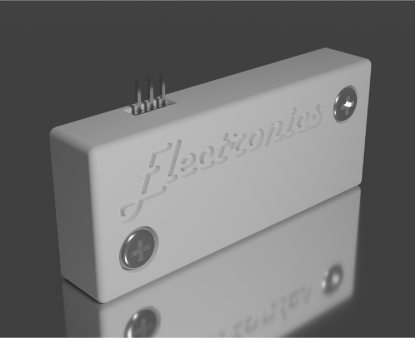

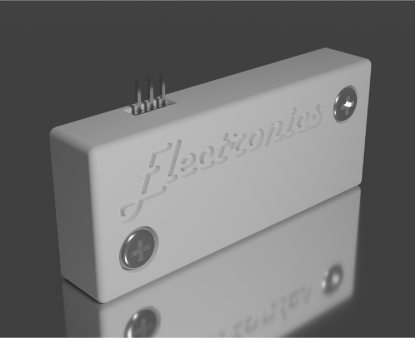

Aesthetics and Ergonomics: An enclosure provides a neat and professional appearance to the PCB assembly. It also facilitates the integration of the PCB into a larger system or product. Enclosures can be designed with features like mounting holes, connectors, and labels for easy installation, maintenance, and user interface.

-

Customization and Branding: Enclosures can be customized to meet specific design requirements or reflect a company's branding. They can be tailored in terms of size, shape, color, and labeling, aligning the PCB with the overall product design or corporate identity.

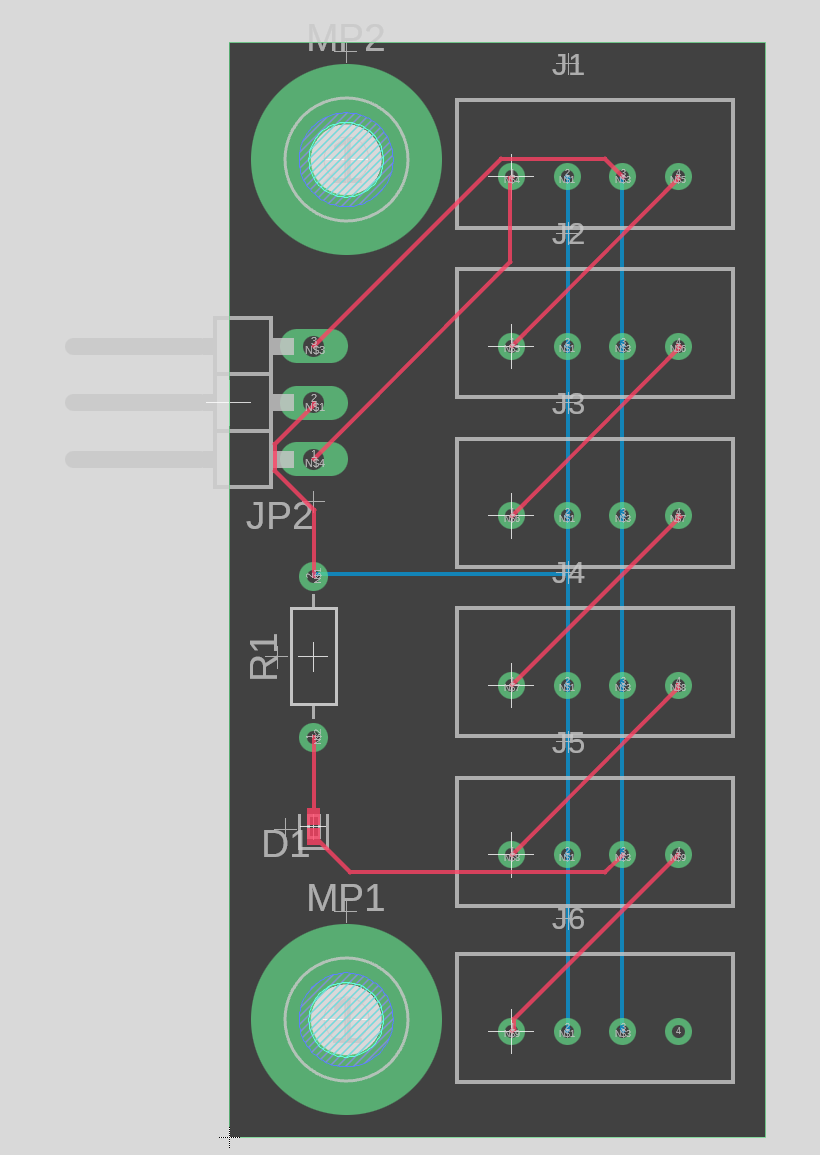

Overall, a PCB enclosure offers protection, safety, compliance, and customization benefits. It ensures the reliability and longevity of the PCB assembly while enhancing its functionality, aesthetics, and integration within a larger system or product. Note: We do help with design layout using Eagle to implement design with enclosures, if this something you need, please feel free to contact us, we will work closely to help you get your PCB done the way you need it.