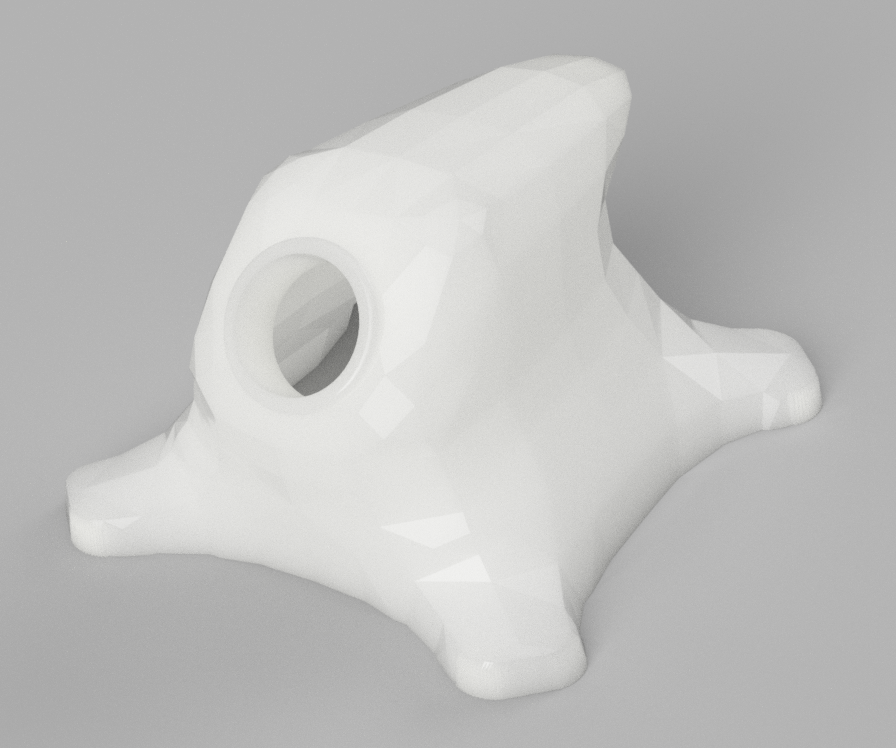

Nylon polyethylene white/smooth

The realm of additive manufacturing has witnessed incredible advancements over the years, transforming the way we conceive, design, and create objects. Among the cutting-edge technologies propelling this revolution, 3D resin printing stands out as a game-changer. This innovative approach offers unparalleled precision, detail, and versatility, unlocking a whole new realm of possibilities for industries ranging from engineering and design to medicine and art. In this article, we explore the world of 3D resin printing, delving into its working principles, applications, benefits, and the exciting potential it holds for the future.

Understanding 3D Resin Printing

3D resin printing, also known as stereolithography (SLA) or digital light processing (DLP), is an additive manufacturing process that utilizes liquid resin materials to create intricate 3D objects layer by layer. Unlike traditional 3D printing methods that rely on filament or powder, 3D resin printing uses a photosensitive liquid resin that hardens when exposed to specific wavelengths of light.

The Process: In both SLA and DLP printers, the process begins by creating a digital 3D model using computer-aided design (CAD) software. The printer's software then slices the 3D model into thin layers. The liquid resin is housed in a vat, and a build platform is submerged at the bottom. A light source (laser or projector) then exposes the resin layer by layer, solidifying the resin and creating the object. As each layer hardens, the build platform gradually moves upward, bringing the final 3D object to life.

Key Advantages of 3D Resin Printing

- Exceptional Precision: 3D resin printing boasts remarkable accuracy and precision, allowing for the creation of intricate geometries and fine details that surpass the capabilities of traditional 3D printing technologies. This makes it a preferred choice for producing high-quality, complex prototypes and end-use parts in various industries.

- Wide Range of Materials: Resin 3D printing supports various materials, each tailored to specific applications. Standard resins offer excellent resolution and are suitable for general use, while specialized resins cater to industries like dentistry, jewelry, engineering, and biomedicine.

- Smooth Surface Finish: Objects created through 3D resin printing showcase a smooth, polished surface finish, reducing the need for extensive post-processing work. This advantage is particularly valuable for industries where aesthetics play a crucial role.

Applications of 3D Resin Printing

- Prototyping: 3D resin printing enables rapid prototyping, facilitating the development of functional prototypes with precise dimensions and detailing. This aids in streamlining product development processes and reducing time-to-market for various industries.

- Dentistry and Orthodontics: Dental labs employ 3D resin printers to produce accurate dental models, crowns, aligners, and other orthodontic appliances. The technology enables dentists to offer personalized treatment plans with better-fitting and more comfortable solutions for patients.

-

Jewelry Design: Resin 3D printing is a boon for jewelry designers as it allows them to create intricate and delicate designs that were once difficult to achieve through traditional methods. The technology empowers artists to unleash their creativity, resulting in unique and stunning jewelry pieces.

-

Engineering and Manufacturing: In engineering, 3D resin printing facilitates the production of complex prototypes, jigs, fixtures, and tooling with precise tolerances. It also holds promise for small-scale production runs of specialized parts.

-

Medical Applications: The medical field benefits greatly from 3D resin printing for creating patient-specific anatomical models, surgical guides, and prosthetics. It aids in surgical planning, medical education, and improving patient outcomes.

Conclusion

3D resin printing stands as a testament to human ingenuity, unlocking new frontiers in additive manufacturing. Its unparalleled precision, versatility, and wide-ranging applications have made it an indispensable tool across industries, propelling innovation and creativity to new heights. As the technology continues to evolve, we can anticipate even more groundbreaking applications and advancements, shaping the future of manufacturing and design as we know it.